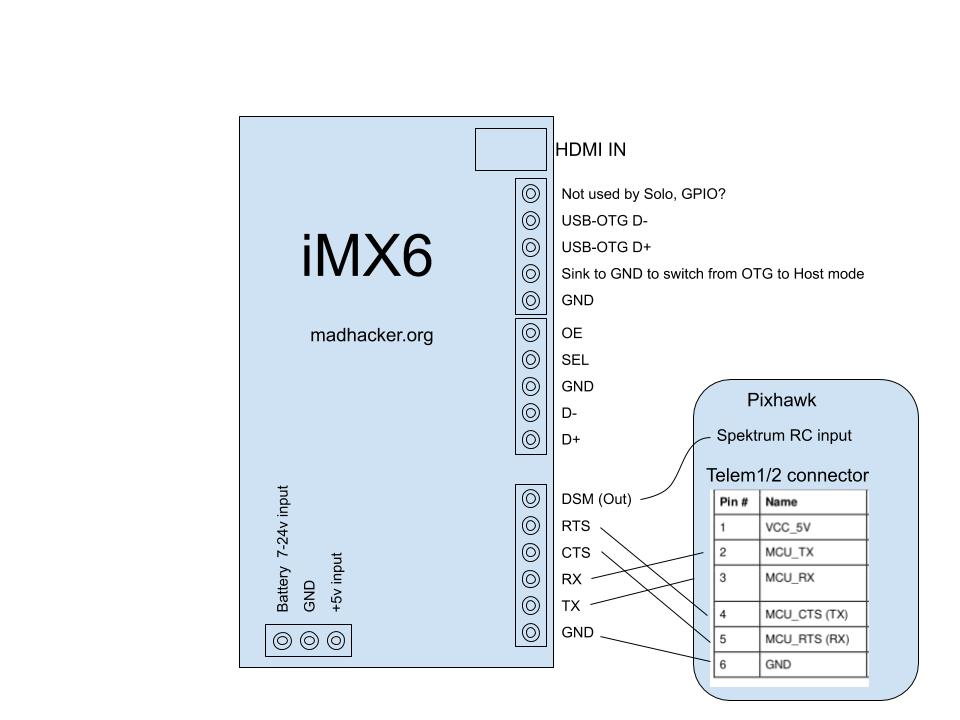

3DR Solo, have a great onboard computer, the IMX6 runs Yocto Linux : link to the Linux source: https://github.com/OpenSolo/imx6-linux

Among it’s best features is the HDMI-in, USB, and mini-PCIe port which can easily use rather powerful MicroTik router/Wi-Fi modules.

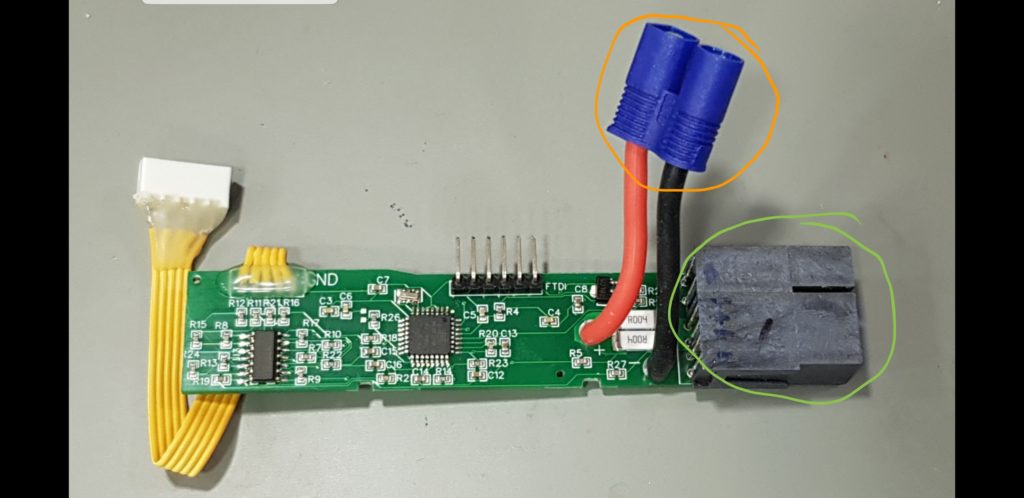

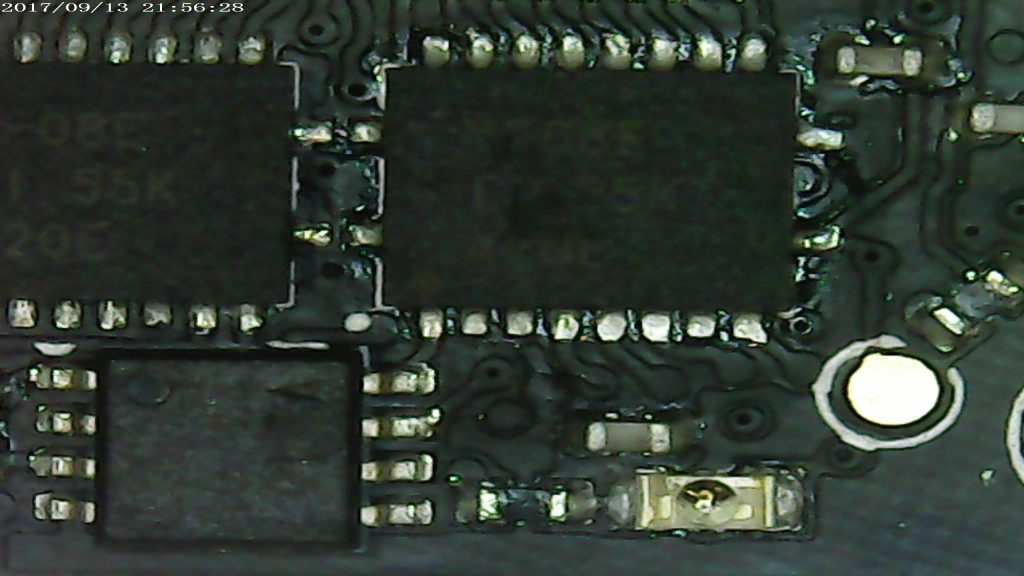

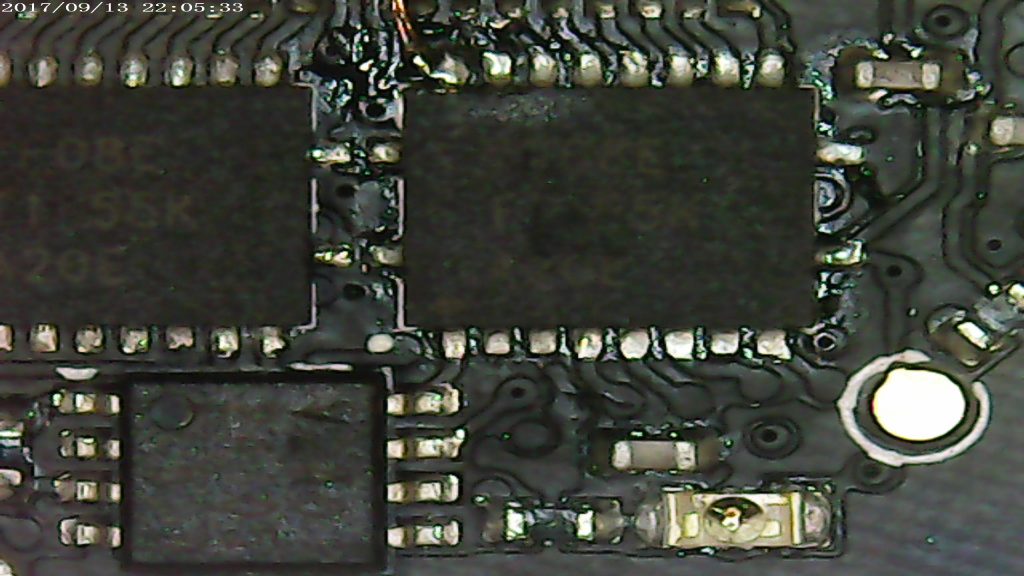

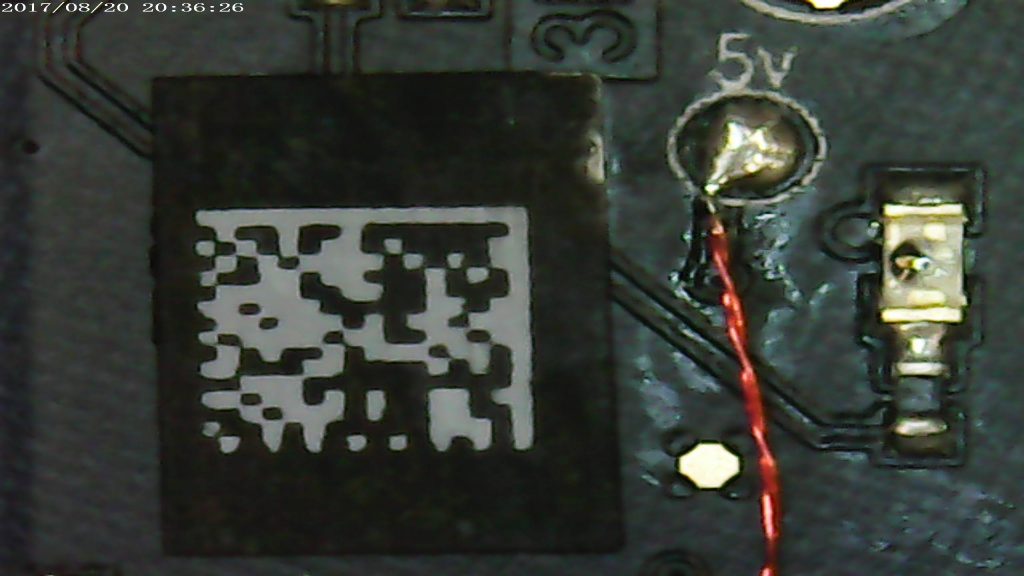

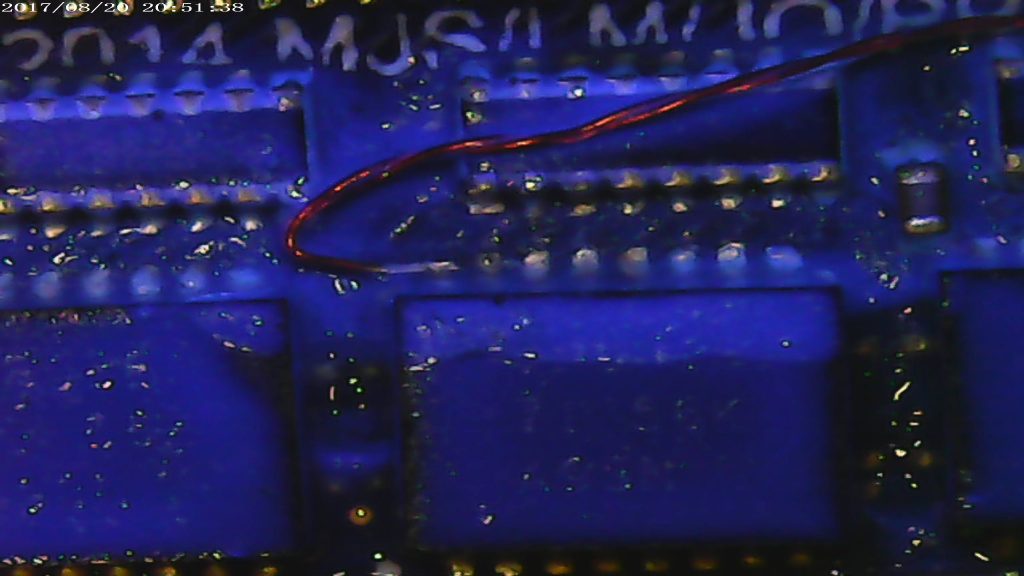

I reverse-engineered the remaining pins, as only the 3 and 6 pin headers were known to the community.|

Battery 7-24v, is the main power source.

+5v input does not seem to be essential for normal operation.

First USB host (D+,D-) is a normal USB2.0 host, compatible.

SEL(select) and OE(output enable) are two GPIO pins used by Solo to select where this USB host is connected: During normal operation the OE control if it is connected to any device (or not) and SEL controls if it is connected to the Cube (for firmware upgrade via bootloader) or the gimbal bay connector.

Unless you need more than two USB devices, you can ignore SEL and OE, and just use D+/D- for the USB host as usual.

Then there is the USB-OTG port. If you pull down the “Sink to GND…” pin, then the USB-OTG port becomes another USB host port. Otherwise, the USB-OTG port is in OTG mode, and will act as a slave/device – so that you can connect it directly to another host(usually a computer) This pin is not routed to anything on the Solo main board I tested.

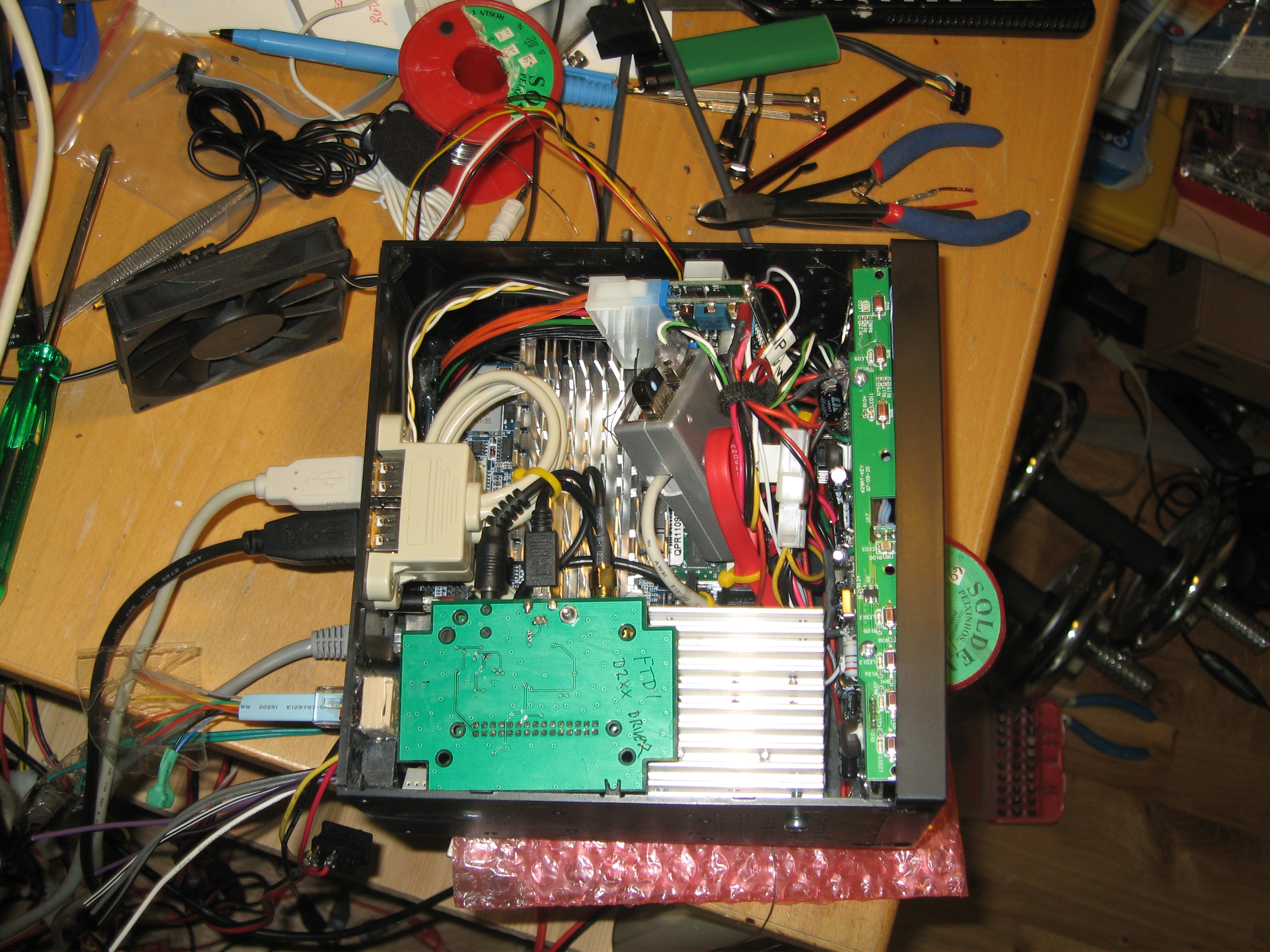

The default onboard Linux is compiled only with FTDI and CDC-ACM (Communication Device Class – Abstract Control Model) profile, so it will instantly work with all kinds of Arduino/STM32’s that normally show up as a ttyUSB or ttyACM device.

DSM outputs a Spektrum RC control signal from the Solo Controller, it is optional to use it.

Finally, there is the usual RTS, CTS, RX, TX that is used for MAVLink telemetry, the hardware flow control is optional.

There is one more pin “not used by Solo” that is not routed anywhere, but on the iMX6 it is certainly connected to something, maybe another GPIO

As-Is, you can take out the iMX6 from a Solo, and use it and a Solo controller with any MAVLink source.

If no MAVLink stream is presented, everything else will still work, but the controller will auto-sleep after 10minutes or so. This could probably be easily fixed/changed in the controller’s software.

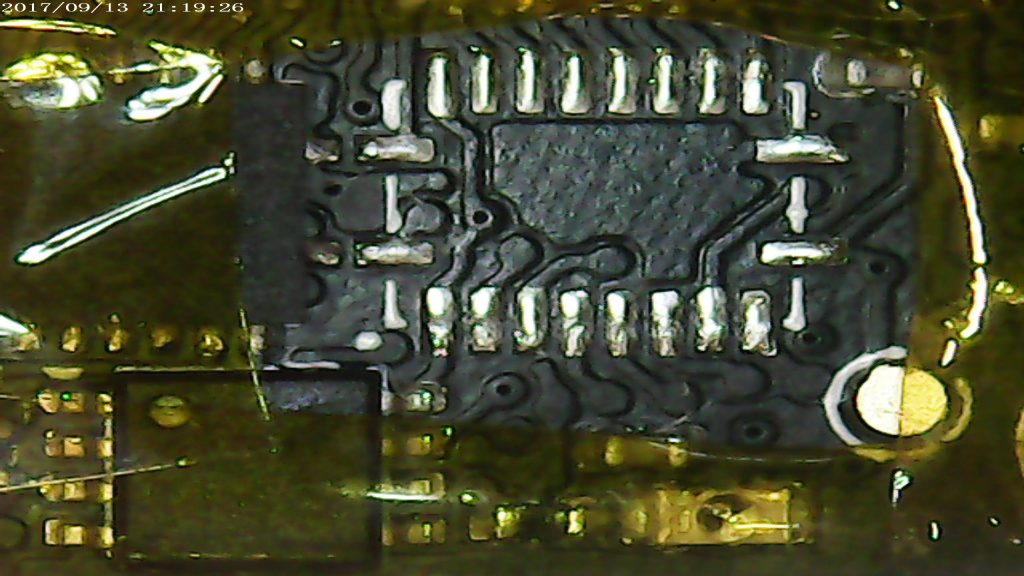

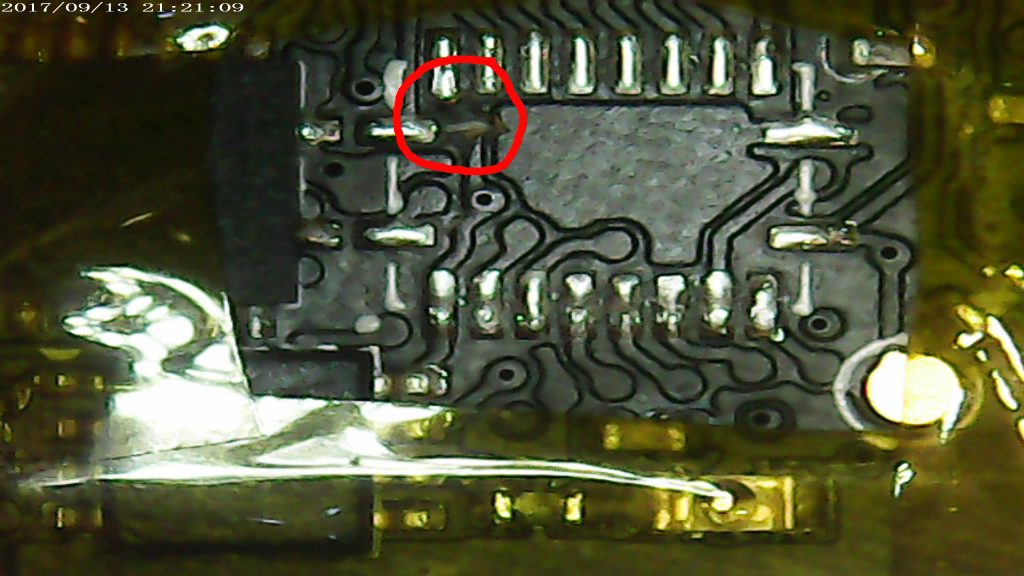

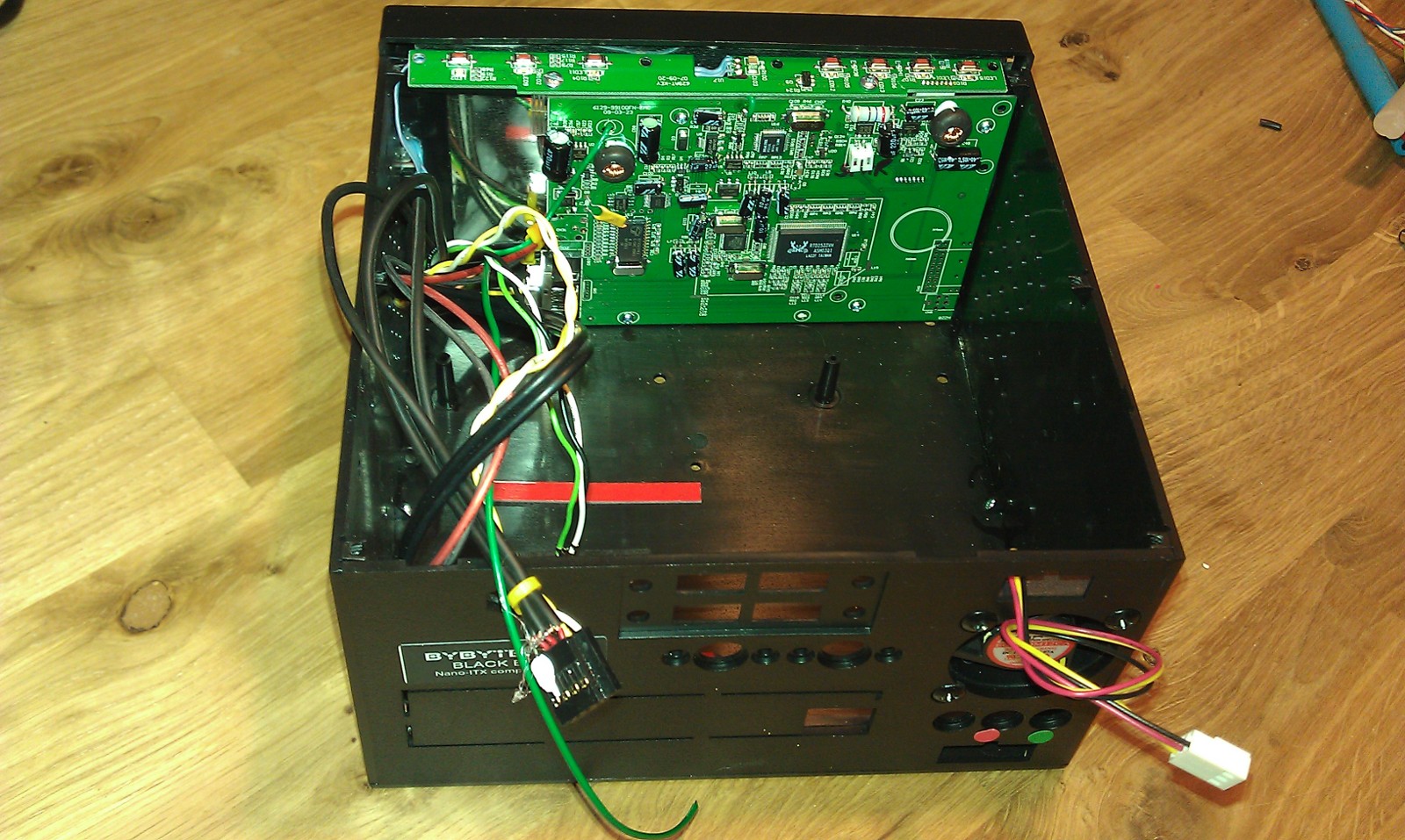

This is the inside of XBOX’s rear shielding plate.,

This is the inside of XBOX’s rear shielding plate.,